Humanoid Robot Safety Standards 2026: Ensure Compliance

Humanoid Robot Safety Standards: The Evolving 2026 Compliance Landscape

Key Takeaway

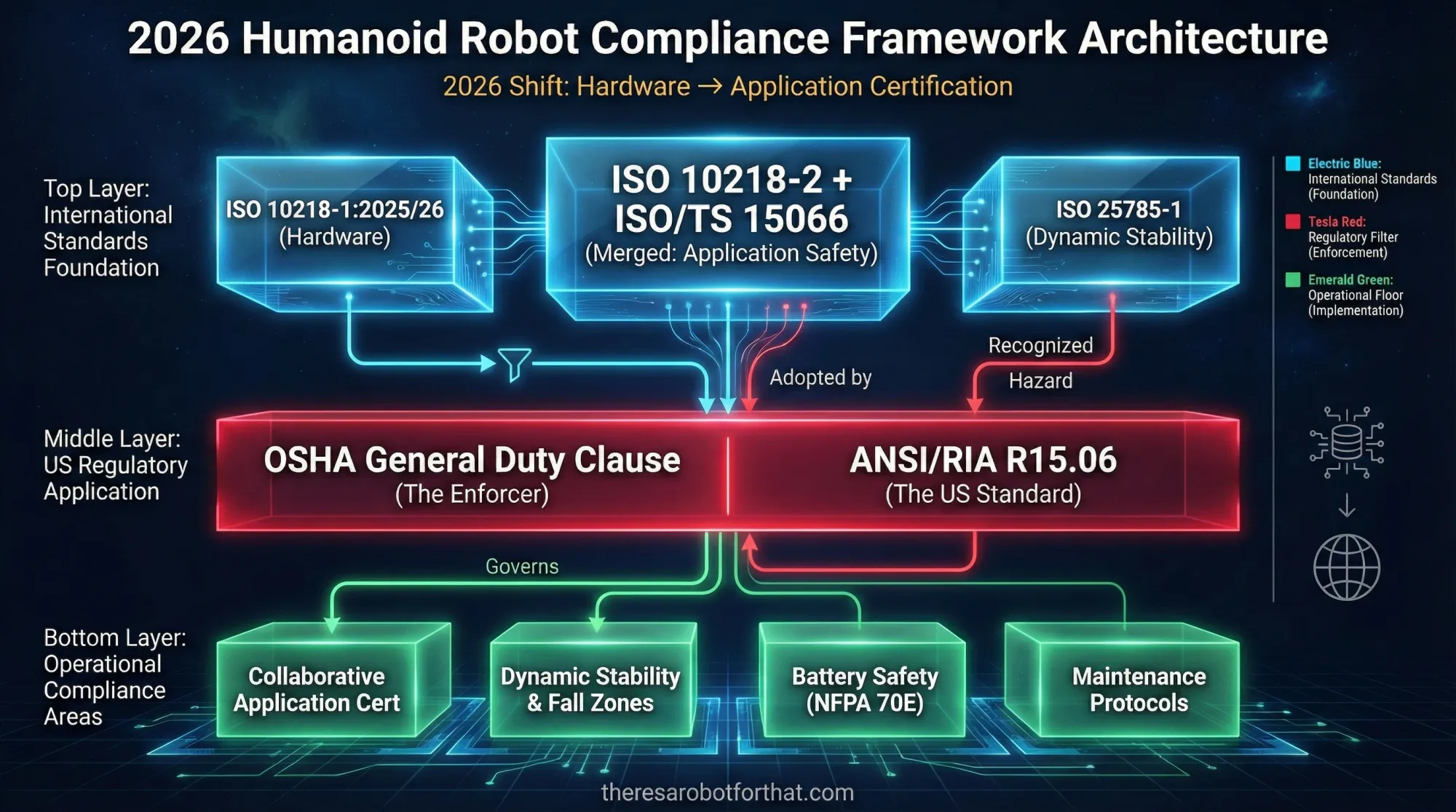

Humanoid robot safety in 2026 is governed by ISO 10218:2025 and ANSI/A3 R15.06-2025, with ISO 25785-1 under development specifically for dynamically stable robots.

- Certification now covers applications, not just hardware

- Walking robots require fall zone calculations based on manufacturer specifications

- Hot-swap batteries need thermal management protocols per manufacturer guidelines

Last updated: 16 January 2026

Your facility bought a "collaborative" humanoid robot. The vendor said it's safe. Six months later, OSHA cites you for an unsafe application. The robot hasn't changed. Your deployment failed compliance.

Traditional collaborative robot rules don't cover walking machines. ISO/TS 15066 addressed contact forces for stationary arms. Humanoid robots walk, balance, and carry energy-dense batteries. Different risks need different standards.

This guide explains the current regulatory framework and emerging standards. You'll learn how ISO 10218-1:2025 shifted from hardware to application certification. You'll understand the developing ISO 25785-1 requirements for dynamic stability. You'll see how OSHA applies existing rules to walking robots.

For a complete implementation roadmap covering infrastructure, training, and ROI, see our Step-by-Step Humanoid Robot Implementation Guide.

The 2025/26 Regulatory Shift: From "Cobot" to "Application"

The 2025 update to ISO 10218-1 shifts safety focus from hardware definitions to collaborative application certification. Buying a robot with force-limiting joints no longer guarantees compliance.

The term "collaborative robot" implied the machine itself was inherently safe. A robot arm that stopped on contact met the definition. Regulators now recognize that safety depends on the entire system. The robot, the task, the workspace, and the human workflow all contribute to risk.

ISO 10218-1:2025 defines "collaborative application" as the complete operational setup. Your risk assessment must cover the process, not just the robot. A safe robot performing an unsafe task fails compliance.

ISO/TS 15066 provided biomechanical force limits for human-robot contact. Those limits remain scientifically valid. The 2025 update integrates them into ISO 10218-2 rather than maintaining a separate technical specification. The data didn't change. The regulatory structure did.

This shift affects insurance premiums. Insurers now audit your deployment process. They verify that your collaborative application matches your risk assessment. A mismatch voids coverage. One facility installed humanoid robots in a workspace designed for wheeled AGVs. The floor layout created blind corners. The insurance audit flagged it. Premium doubled.

Hardware certification is necessary but insufficient. Application certification requires documentation of task analysis, workspace layout, and human interaction patterns. Your vendor can certify the robot. Only you can certify the application.

The previous framework evaluated robot capabilities.

The current framework evaluates deployed systems.

Re-assess every application using ISO 10218-1:2025 and ISO 10218-2:2025 criteria before continuing operations.

ISO 25785-1: The Emerging Standard for "Walking Robots"

ISO 25785-1, currently under development, will establish safety requirements for dynamically stable robots—machines that require active balance control to remain upright. Traditional robot arms bolt to the floor. Humanoid robots walk. Walking introduces fall risk.

Important: As of January 2026, ISO 25785-1 remains a Working Draft. The ISO working group, led by experts from Agility Robotics, Boston Dynamics, and the A3 Association, held its most recent session in Barcelona in October 2025. Final publication is expected in 2026 or 2027. Until then, facilities should apply its principles as best-practice guidance while relying on ISO 10218 and manufacturer specifications for compliance.

A stationary arm in a known position presents predictable hazards. A walking robot that loses power tips over. The direction and distance of the fall depend on speed, load, and floor angle. ISO 25785-1 aims to quantify that variability.

"Active Balance Control" means the robot continuously adjusts joint positions to maintain upright posture. Sensors detect tilt. Actuators correct it. This happens hundreds of times per second. The draft standard proposes performance thresholds for balance recovery under rated load.

The "Fall Zone" is the area where the robot could land if balance fails. Calculate it using robot height, stride length, and maximum walking speed. A typical 1.7-meter robot moving at 1.5 m/s has a fall zone extending approximately 2 meters in any direction—though exact calculations should follow manufacturer guidelines. Mark that zone on your floor. No workers inside during operation.

Floor conditions affect stability. Oil residue reduces friction. Expansion joints create trip points. The robot's balance algorithm needs accurate floor data. One automotive plant deployed humanoids on epoxy-coated concrete. The coating's friction coefficient differed from the training simulation assumptions. Robots fell during turns. The facility had to recoat the affected area.

Most manufacturers implement "zero-energy pose" protocols. If the robot loses power, it assumes a position that minimizes fall damage. Most humanoids drop to a kneeling position. This reduces fall height significantly. Impact force drops correspondingly.

For detailed floor and infrastructure requirements, see our Site Readiness Checklist in the Implementation Guide.

Operational Safety: Hot-Swap Battery Protocols

Safety protocols for hot-swappable batteries require thermal management and designated swap zones. Manufacturers like Agibot design their G2 and A2-W models to support battery changes during operation. This capability introduces thermal and electrical risks.

Thermal runaway occurs when a battery cell overheats and ignites adjacent cells. Hot-swapping removes cooling while the cell is active. If the replacement battery misaligns, arcing can trigger runaway. The risk is highest in the brief window between removal and insertion.

Arc flash happens when connectors separate under load. A 48V battery at 60A creates significant arc potential. Modern systems use recessed connectors to contain arcs. The recess channels plasma away from the operator.

Hot-Swap Safety Protocol (General Guidelines)

Step 1: Verify thermal state. Check the battery temperature display. If above manufacturer-specified thresholds (typically 40-50°C), wait. Do not force insertion—this bypasses thermal protection and voids safety certification.

Step 2: Position in the swap zone. The robot must stand in a marked area, away from flammable materials. Minimum clearance should be at least 1.5 meters from walls or equipment. The zone should have appropriate fire suppression within reach.

Step 3: Engage mechanical guides. The battery slides into alignment rails. These guides prevent angular misalignment. Even small misalignment can cause connector damage. The guides are typically self-centering and require no tools.

Step 4: Remove the depleted battery. Pull straight back. Do not twist. The connectors disengage under spring tension. If resistance exceeds normal, stop. Forcing it may indicate a thermal lock. Let the system cool.

Step 5: Insert the fresh battery. Slide forward until the mechanical latch clicks. The system runs a continuity check. A green indicator confirms proper seating. If the indicator stays red, remove and reinsert.

Step 6: Verify operational status. The robot will display battery health data. Confirm voltage is within manufacturer specifications. If outside range, remove the battery and inspect connectors for debris or damage.

Hot-swap capability can reduce downtime by 90% compared to full shutdowns. The safety trade-off is added protocol complexity. Operators need training on thermal monitoring and alignment procedures. Facilities that skip training report higher incident rates. After proper training, incidents typically drop to near zero.

Operational procedures like these are part of Phase 3 pilot programs. See our Implementation Guide for pilot structure recommendations.

US Compliance: OSHA & ANSI/A3 R15.06-2025

OSHA regulates humanoid robots under the General Duty Clause (Section 5(a)(1)) and references ANSI/A3 R15.06-2025. The General Duty Clause requires employers to provide a workplace "free from recognized hazards." No specific OSHA standard addresses humanoid robots. Inspectors apply the General Duty Clause.

A "recognized hazard" is one the industry knows how to prevent. ISO and ANSI standards define prevention methods. If your facility ignores ISO 10218 or developing standards like ISO 25785-1, OSHA can cite you. The citation references the General Duty Clause, but the evidence is your failure to follow consensus standards.

ANSI/A3 R15.06-2025, published in October 2025, represents the US national adoption of ISO 10218 Parts 1 and 2. The A3 Association for Advancing Automation maintains this standard for US facilities. Key updates include:

- Clarified functional safety requirements that improve usability and compliance

- Integrated guidance for collaborative applications, consolidating ISO/TS 15066

- Cybersecurity requirements as part of safety planning

- Updated robot classifications with corresponding safety functions

Lockout/Tagout (LOTO) creates a unique challenge for humanoid robots. Standard LOTO requires de-energizing equipment during maintenance. A humanoid robot that loses power falls over. Maintenance on a fallen robot is more dangerous than maintenance on a powered, stable one.

OSHA allows "Control of Hazardous Energy" procedures as an alternative to full LOTO. The robot remains powered but locked in a safe mode. Joints freeze in position. The balance system stays active. The work envelope is restricted. This approach satisfies OSHA if documented in your energy control program.

One Midwest manufacturer faced an OSHA inspection after a worker injury. The robot didn't cause the injury, but the inspector audited all robotic systems. The facility had humanoid robots with no documented energy control procedures. OSHA cited them under the General Duty Clause. The fine was $15,400 per robot. Seven robots meant $107,800 in penalties.

Compliance requires three documents: a collaborative application risk assessment, an energy control procedure, and operator training records. The risk assessment must reference ISO 10218. The energy control procedure must explain why full LOTO is unsafe. Training records must show that operators understand fall zones and battery protocols.

OSHA inspectors increasingly ask about digital safety systems. If your robot uses AI for obstacle avoidance, the inspector will ask how you validated it. "The vendor said it works" is not an acceptable answer. You need test data showing the system detects humans at the required distance.

For comprehensive compliance engineering guidance, see Phase 4: Safety & Compliance in our Implementation Guide.

Implementation: The Risk Assessment Matrix

A compliant risk assessment matrix must categorize hazards by dynamic stability, energy storage, and human-robot interaction zones. The matrix visualizes risks and maps them to mitigation strategies.

Each hazard category links to a governing standard or best practice. Your assessment must reference the specific section of the standard that applies. This creates an audit trail. An inspector can verify that your mitigation strategy matches the regulatory requirement.

| Hazard Category | Risk Description | Governing Standard/Guidance | Mitigation Strategy |

|---|---|---|---|

| Dynamic Stability | Robot falling during power loss | ISO 25785-1 (developing) / Manufacturer specs | Zero-energy pose protocols, fall zone markings |

| Energy Storage | Thermal runaway during hot-swap | Manufacturer protocols / NFPA 70E | Thermal monitoring, swap zone with fire suppression |

| Interaction | Impact during collaboration | ISO 10218-2:2025 | Speed & Separation Monitoring, force-limited joints |

| Mobility | Collision with workers in shared space | ISO 10218-2:2025 | LIDAR-based detection, audible warnings, restricted zones |

| Maintenance | Injury during service with active balance | OSHA 1910.147 / ANSI/A3 R15.06-2025 | Control of Hazardous Energy procedures, lockout alternatives |

| Electrical | Arc flash during battery connection | NFPA 70E | Recessed connectors, PPE requirements, thermal cutoffs |

The "Dynamic Stability" row addresses the unique risk of walking robots. Traditional risk assessments don't include this category. A facility using the old matrix will miss fall-related hazards. Your matrix must explicitly list stability as a separate category.

"Energy Storage" covers battery risks. Hot-swappable systems concentrate energy in a small, frequently handled package. The mitigation strategy must reference both manufacturer protocols and NFPA 70E electrical safety standards.

"Interaction" risks apply to all collaborative robots. Speed and Separation Monitoring (SSM) is the most common mitigation. The robot slows or stops when a human enters a defined zone. ISO 10218-2:2025 requires SSM systems to account for both robot and human speed.

"Mobility" is distinct from interaction. Interaction assumes the human and robot are working together. Mobility addresses the robot moving through shared space. A humanoid walking to a charging station might encounter a worker in a hallway. LIDAR detects the worker. The robot stops or reroutes.

"Maintenance" requires special attention for humanoid robots. The robot must stay powered to remain upright. Your energy control procedure must define how maintenance happens safely. Most facilities use a "safe mode" where the robot stands still but remains balanced.

"Electrical" hazards increase with hot-swappable batteries. NFPA 70E defines arc flash boundaries and PPE requirements. Your risk assessment must specify the incident energy level at the battery connector. Most systems require Category 1 PPE: flame-resistant shirt and pants, safety glasses, and insulated gloves.

Common Compliance Mistakes

Assuming hardware certification equals application approval. The robot's CE mark certifies the hardware. Your workspace needs separate certification. OSHA cites the application, not the robot.

Using generic risk assessments from the vendor. Vendor templates describe the robot. Your assessment must describe your facility. Floor conditions, task sequences, and worker patterns are site-specific.

Ignoring fall zones during layout planning. Facilities measure robot footprints and forget fall zones. A 0.6-meter footprint may have a 2-meter fall zone. Plan for the larger number.

Skipping thermal monitoring on battery swaps. Operators swap batteries on schedule, not temperature. A battery at 50°C looks identical to one at 40°C. Install temperature displays at swap zones.

Treating humanoid robots like wheeled AGVs. AGVs follow fixed paths. Humanoid robots navigate dynamically. Your safety protocols must account for unpredictable routes.

Waiting for ISO 25785-1 to finalize. The standard is still developing, but the hazards exist now. Apply best practices from the working draft and manufacturer specifications today.

Limitations & Alternatives

Current humanoid robot safety standards apply primarily to collaborative applications. If your facility uses fully fenced robots, ISO 10218-1 Part 1 (industrial robots) applies instead. Fencing eliminates human-robot interaction. Compliance is simpler.

ISO 25785-1, once published, will assume the robot operates on level ground. Slopes above 5 degrees may require site-specific stability analysis. The standard will provide formulas, but you may need engineering consultation. Facilities with significant grade changes should engage robotics engineers for custom fall zone calculations.

Hot-swap battery protocols work for standardized systems with built-in thermal monitoring. Custom-built robots may lack these features. In those cases, full shutdown for battery changes is safer. The downtime cost may be lower than the risk of thermal runaway.

OSHA's General Duty Clause is a catch-all. It applies when no specific standard exists. As humanoid robots become common, OSHA may issue a dedicated standard. That standard could be more prescriptive than current ISO guidelines. Facilities should monitor OSHA rulemaking.

Conclusion

Humanoid robot safety in 2026 centers on established and emerging frameworks:

- ISO 10218:2025 certifies collaborative applications, not just hardware

- ISO 25785-1 (under development) will manage fall risks through balance metrics and zone calculations

- ANSI/A3 R15.06-2025 provides the US national standard for industrial robot safety

- Manufacturer protocols address specific risks like hot-swap battery management

Compliance protects workers and limits liability. A certified application reduces insurance premiums. Documented risk assessments defend against OSHA citations. Training records prove due diligence.

The regulatory shift from hardware to application changes how facilities deploy robots. Buying a safe robot is step one. Certifying a safe deployment is step two. Most violations happen in step two.

Humanoid robots walk, balance, and carry energy. Traditional rules didn't account for those risks. The evolving standards do. Apply them now—don't wait for final publication.

FAQ

What are the safety standards for humanoid robots in 2026?

The primary standards are ISO 10218-1:2025, ISO 10218-2:2025, and ANSI/A3 R15.06-2025. ISO 10218 focuses on collaborative applications rather than hardware alone. The entire workspace must be assessed. ISO 25785-1, currently under development, will specifically address dynamically stable robots including humanoids. Until its publication, facilities should follow manufacturer specifications and ISO 10218 principles.

Is ISO/TS 15066 still valid for collaborative robots?

ISO/TS 15066 has been integrated into ISO 10218-2:2025. The biomechanical limits for force and pressure remain valid. They are no longer a standalone specification. Compliance now requires the broader collaborative application framework within ISO 10218.

What are the safety risks of hot-swappable robot batteries?

The primary risks are thermal runaway and arc flashes from misalignment. Protocols require mechanical guides for alignment, software thermal monitoring, and designated swap zones away from flammable materials. Specific temperature thresholds vary by manufacturer.

How does OSHA regulate walking robots?

OSHA uses the General Duty Clause (Section 5(a)(1)) and references ANSI/A3 R15.06-2025. No specific humanoid standard exists yet. Inspectors verify adherence to consensus standards like ISO 10218 and manufacturer safety specifications. Failure to follow recognized standards can be cited as a recognized hazard.

When will ISO 25785-1 be published?

ISO 25785-1 is currently a Working Draft with publication expected in 2026 or 2027. The ISO working group includes representatives from Agility Robotics, Boston Dynamics, and A3. Until final publication, facilities should apply the draft's principles as best practices alongside ISO 10218 requirements.

References

- ISO 10218-1:2025 - Robotics — Safety requirements — Part 1: Industrial robots - https://www.iso.org/standard/73933.html

- ISO 25785-1 (Working Draft) - Safety requirements for dynamically stable industrial mobile robots - https://www.iso.org/standard/91469.html

- OSHA Robotics Standards and General Duty Clause - https://www.osha.gov/robotics/standards

- A3 Association - Updated ISO 10218 FAQ - https://www.automate.org/robotics/blogs/updated-iso-10218-faq

- Agibot G2 Product Specifications - https://www.agibot.com/products/G2

- Figure AI - BMW Production Deployment Results - https://www.figure.ai/news/production-at-bmw

- Agility Robotics - Digit Solution Overview - https://www.agilityrobotics.com/solution